Mold Design

- A leader in plastic injection molding

- Injection Molding Cost Calculator, Get Online Quotes in 24Hours

- Parts shipped in as little as 15 days

- The world’s only 24-Hours injection molding quote

- Low-Cost Injection Molding Leader

- All uploads are secure and confidential

15⁺

16

2

3

Our Custom Injection Molding Design Capabilities

![]() With Formex’s 15+ years of injection mold design expertise, your ideas become manufacturable, scalable, and competitive.

With Formex’s 15+ years of injection mold design expertise, your ideas become manufacturable, scalable, and competitive.

![]() 15+ Years of Experience: Specializing in complex mold projects.

15+ Years of Experience: Specializing in complex mold projects.

![]() Proprietary Technology: Advanced CAM software and automation for defect-free molding.

Proprietary Technology: Advanced CAM software and automation for defect-free molding.

![]() Serving 500+ projects with complex molding challenges.

Serving 500+ projects with complex molding challenges.

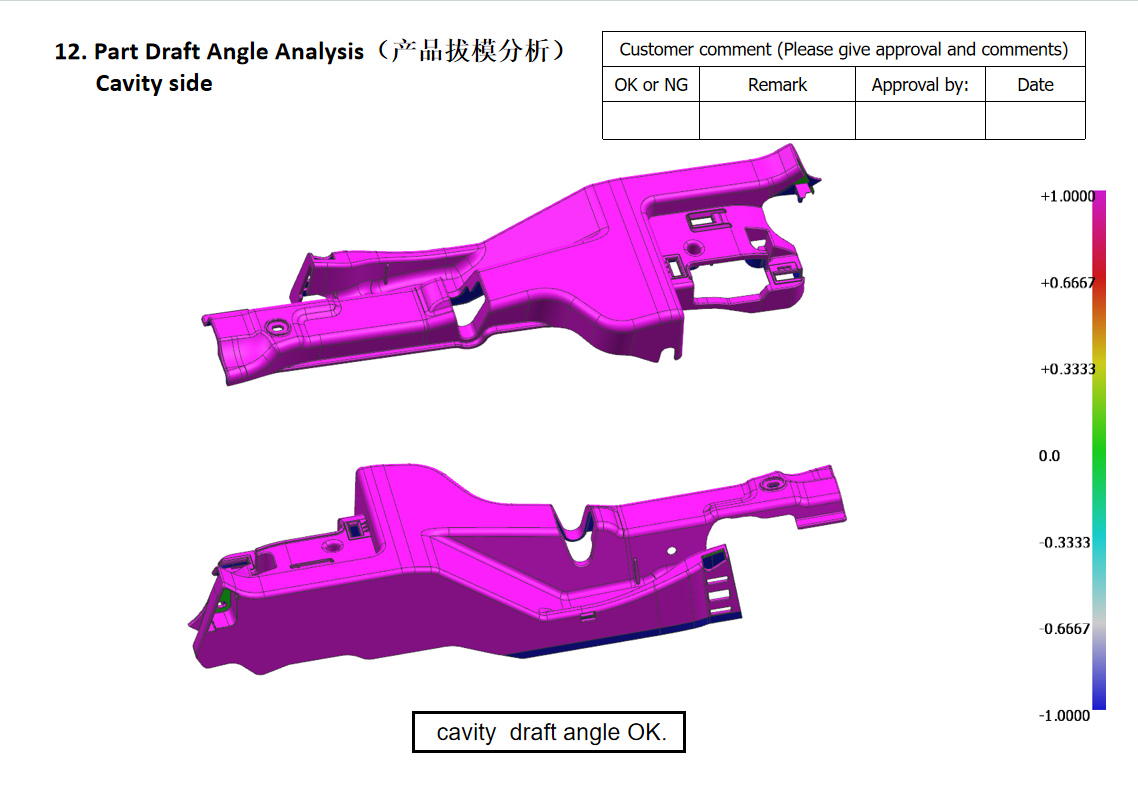

DFM Report

Our DFM analysis service ensures manufacturability by addressing critical issues early in the design phase. Depending on various types of manufacturing processes there are set guidelines for DFM practices that help to precisely define various tolerances, rules, and common manufacturing checks.

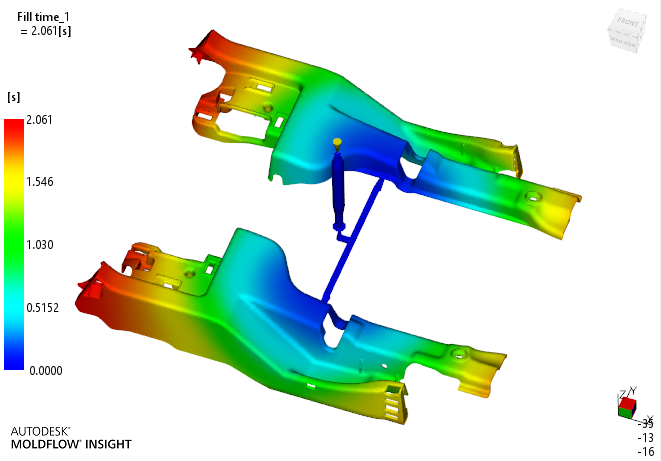

Moldflow Analysis

MoldFlow provides simulation tools for injection mold design. By iterating molding simulations, our team can optimize product designs, mold designs, and prevent multiple modifications to the mold, reducing costs and time.

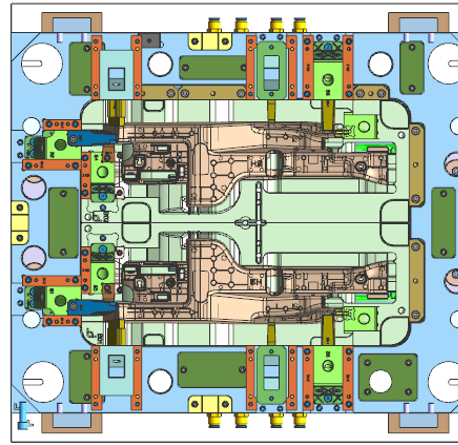

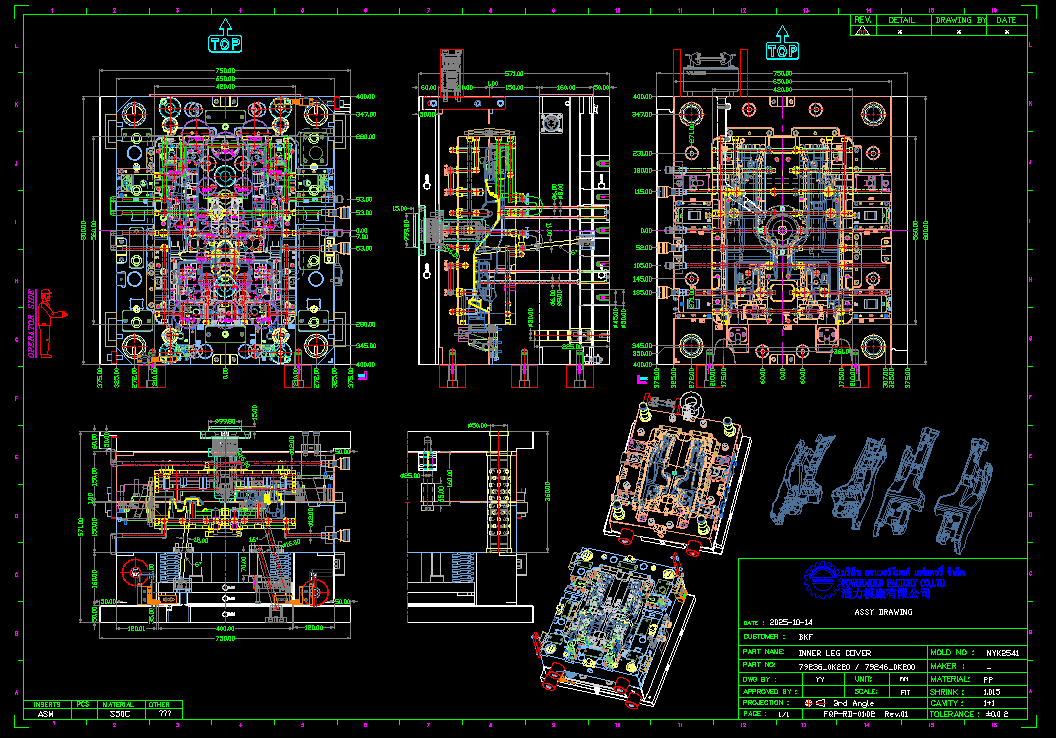

2D & 3D Mold design

With 2D & 3D design, we can help our clients figure out changes or improvements needed for the product. We can check all the details in the mold and avoid the possibility of mistakes.

Complex Geometric Design

Specializing in advanced mold solutions for intricate structures like thin-walls, curved surfaces, undercuts, and threads. SolidWorks/UG NX for ultra-accurate designs. Multi-slide/side-core technology to conquer challenging geometries./span>

Common Solutions to Avoid Issues in Mold Design:

I. Mold Structure Design Issue Avoidance

1-1. Unreasonable parting surface design The parting surface should avoid product appearance and assembly surfaces, while ensuring the product can be smoothly demoulded to prevent sticking. Before design, simulate the mould opening trajectory and check for sharp corners or thin edges on the parting surface to prevent issues such as chipping or excessive flash during mold production.

1-2. Defects in demoulding mechanism design The arrangement of ejector pins and blocks should be evenly distributed to avoid excessive local stress that may deform the product. For deep cavity or thin-walled products, add auxiliary demoulding mechanisms (such as push plates or inclined ejectors) and check the ejection stroke to ensure the product can fully separate from the mold cavity after demoulding.

1-3. Insufficient guiding and positioning accuracy The mold’s guide pins and bushings should be made of wear-resistant materials, with sufficient length and fit precision to avoid misalignment or jamming during clamping. For high-precision molds, add positioning pins for auxiliary alignment, ensuring the cavity-core alignment error is within 0.005mm.

2. Mold Material and Heat Treatment Issue Avoidance

2-1. Improper material selection Choose mold steel according to product production volume and material (such as plastic or metal): for high-volume injection molds, prefer wear and corrosion-resistant steels like H13 or S136; for stamping dies, use high hardness steels like Cr12MoV. Ordinary carbon steel should not be used as a substitute for specialized mold steel to avoid premature wear or deformation.

2-2. Substandard heat treatment process Key mold components (cavities, cores, punches) need standardized heat treatment, controlling quenching temperature and tempering cycles to ensure hardness and relieve internal stress. Conduct flaw detection after heat treatment to avoid defects such as cracks or soft spots, preventing edge chipping or breakage during mold use.

3. Avoiding Design Issues in Cooling and Venting Systems

1-1. Uneven Cooling System

The cooling channels should closely follow the cavity and core surfaces and be designed with parallel circuits to ensure consistent water flow speed across all circuits, avoiding significant local temperature differences in the mould that may cause uneven shrinkage, deformation, or warping of the product. The diameter and spacing of the channels should be calculated based on the product size, and temperature monitoring points should be installed at the inlet and outlet.

1-2. Clogged or Insufficient Venting System

Vent grooves should be provided at the ends of the mould cavities, parting surfaces, and gaps around inserts. The depth of the vent grooves should be less than the allowable flash of the product material (for plastic moulds, typically 0.01–0.03 mm). Prevent grooves from being too deep, which may cause flash, or too shallow, which may hinder air escape, leading to incomplete filling, scorching, or bubbles.

4. Avoiding Issues in Mould Component Machining and Assembly

1. Machining Accuracy Errors

Key components such as cavities and cores should be manufactured using high-precision methods, such as CNC machining or EDM, with strict control over dimensional tolerances and surface roughness. Full-size inspection should be conducted post-machining to ensure conformity with design drawings, preventing dimensional deviations that could lead to product oversize or poor assembly.

2. Improper Control of Assembly Gaps

The fitting gaps of all mould components should be strictly controlled: sliding fits (e.g., guide pins with bushings, inclined guide pins with sliders) should have appropriate clearance to prevent looseness or jamming; fixed fits (e.g., inserts with plates) should use interference or transition fits to avoid looseness or displacement during use. …

5. Avoiding Issues in Product Compatibility and Mold Trial Optimization

1. Ignoring product forming characteristics

Before designing, it is essential to fully understand the forming characteristics of the product materials, such as the melt flow index and shrinkage rate of plastics, or the ductility and springback of metals. Mold cavity dimensions should allow for shrinkage, and the shrinkage rate should be adjusted based on parameters provided by the material supplier and actual trial mold data to prevent product dimensional deviations.

2. Inadequate trial molding verification

After the mold is processed, trial molding should be conducted. Based on defects observed in trial samples (such as flash, deformation, or incomplete filling), adjustments should be made to the mold structure and process parameters. The trial molding should produce at least 50–100 consecutive pieces, and only after confirming stable product quality should mass production be started. It is prohibited to launch production without trial molding.

Our Mold Design Process

![]()

Analysis of product application areas

We begin by thoroughly analyzing your product requirements, application goals, and production objectives. Collaborating closely with you, we gather detailed information, including product specifications, material requirements, functional needs, and potential challenges.

Mould Feasibility Report

Our expert team conducts a comprehensive feasibility study to evaluate the manufacturability and cost-effectiveness of the design. This step helps identify potential challenges and optimize the injection molding design before moving forward.

3D simulation verification

We develop detailed 3D models of the mold using tools like SolidWorks, UG, or Pro/E. These models undergo rigorous simulation tests, including flow analysis and stress testing, to validate performance and optimize production outcomes.

Submit DFM report for customer approval

Once completed, the design is reviewed internally to ensure accuracy and quality. The finalized design is then presented to you for feedback and approval. We promptly implement any revisions needed to meet your expectations.

Prototyping

If required, we offer prototyping services to test the mold design before full-scale production. This step allows additional validation and refinement, minimizing risks in mass production.

Detailed engineering drawings are starting to be modelled

After approval, we create comprehensive engineering drawings that detail all mold specifications, including dimensions, tolerances, and material requirements. These serve as the blueprint for the manufacturing stage. Mold makers will follow these drawings to build the mold with precision.

Low-Cost Injection Molding Leader

The Best Brands Put Their Trust in Formex