Rapid prototyping

Automotive Injection Molding Service: Custom Solutions for Car Parts Manufacturing

- A leader in plastic injection molding

- Injection Molding Cost Calculator, Get Online Quotes in 24Hours

- Parts shipped in as little as 15 days

- The world’s only 24-Hours injection molding quote

- Low-Cost Injection Molding Leader

Introduction to Rapid Prototyping

Rapid prototyping technology, also known as rapid manufacturing technology (abbreviated as RP technology);

English: RAPID PROTOTYPING (abbreviated as RP technology), or RAPID PROTOTYPING MANUFACTURING, abbreviated as RPM. In the automotive industry, it is called RP samples.

RP technology has been developed based on the integration of modern CAD/CAM technology, laser technology, computer numerical control technology, precision servo drive technology, and new materials technology. Different types of rapid prototyping systems vary in forming materials, principles, and system characteristics. However, the basic principle is the same: “layered manufacturing, layer-by-layer stacking,” which is similar to the mathematical process of integration. Figuratively speaking, a rapid prototyping system is like a “3D printer.”

Advantages

It can directly accept product design (CAD) data and quickly produce prototypes, molds, or models of new products without the need to prepare any molds, tools, or fixtures. Therefore, the promotion and application of RP technology can significantly shorten the development cycle of new products, reduce development costs, and improve development quality. From the traditional “subtractive method” to today’s “additive method,” from mold-based manufacturing to moldless manufacturing, this demonstrates the revolutionary significance of RP technology for the manufacturing industry.Features RP technology breaks down the complex 3D machining of an entity into a series of layered processes, greatly reducing machining difficulty. Its main features are:

(1) Rapid forming process suitable for a highly competitive modern product market;

(2) Ability to manufacture 3D entities of any complex shape;

(3) Directly driven by CAD models, achieving high integration between design and manufacturing, and its intuitiveness and ease of modification provide an excellent environment for perfect product design;

(4) No need for specialized fixtures, molds, or tools during the forming process, saving costs and shortening production cycles;

(5) High technological integration, being both a natural product of modern scientific development and a comprehensive application of various technologies, featuring distinct high-tech characteristics.These features make RP technology mainly suitable for new product development, rapid single-piece and small-batch part manufacturing, complex-shaped parts production, mold and model design and manufacturing. It is also suitable for manufacturing difficult-to-machine materials, appearance design inspection, assembly verification, and rapid reverse engineering.Formation Process Metaphorically, a rapid prototyping system is equivalent to a “3D printer.” It can quickly and directly achieve single-part production without any tools, molds, or fixtures. Depending on the complexity of the part, this process generally takes 1 to 7 days. In other words, RP technology is a method for rapidly and directly manufacturing single parts.

Working principle

Rapid prototyping technology is a new technology that integrates advanced technologies such as computer-aided design (CAD), computer-aided manufacturing (CAM), computer numerical control (CNC), precision servo drives, lasers, and materials science. Its basic concept is that any three-dimensional part can be regarded as many two-dimensional plane contours of equal thickness stacked along a coordinate direction. Therefore, based on the three-dimensional design model created on a computer, the 3D model in the CAD system can first be divided into a series of planar geometric information, i.e., layered slicing, to obtain the contour of each layer’s cross-section. According to these contours, a laser beam selectively cuts layer by layer of paper (or cures layer by layer of liquid resin, sinters layer by layer of powdered material), or a spraying source selectively sprays layer by layer of adhesive or thermoplastic material, forming the cross-sectional contours and gradually stacking them into a three-dimensional product. Rapid prototyping technology completely breaks away from the traditional ‘subtractive’ manufacturing method (i.e., partially removing material from a workpiece to obtain the final part) and adopts a new ‘additive’ manufacturing method (i.e., gradually stacking layers of small stock to build a large workpiece), decomposing complex 3D processing into combinations of simple 2D processing. Therefore, it does not require traditional machining equipment and molds, and only needs 30% to 50% of the labor time and 20% to 35% of the cost of traditional manufacturing methods to directly produce product prototypes or molds. Through rapid prototyping technology, design concepts can be automatically, directly, quickly, and accurately transformed into functional models or directly manufactured products, thereby allowing rapid evaluation, modification, and functional testing of product designs, greatly shortening the product development cycle. Applying rapid prototyping technology in a company’s new product development process can significantly shorten the development cycle of new products, ensure timely market launch, and improve the company’s rapid response to market changes. At the same time, it can reduce mold risks and new product development costs, promptly identify design errors for early correction, avoid substantial losses caused by changes in subsequent processes, and improve the first-time success rate of new product production. Therefore, the application of rapid prototyping technology has become an important strategy in new product development in the manufacturing industry.Rapid prototyping technology is a new technology that integrates advanced technologies such as computer-aided design (CAD), computer-aided manufacturing (CAM), computer numerical control (CNC), precision servo drives, lasers, and materials science. Its basic concept is that any three-dimensional part can be regarded as many two-dimensional plane contours of equal thickness stacked along a coordinate direction. Therefore, based on the three-dimensional design model created on a computer, the 3D model in the CAD system can first be divided into a series of planar geometric information, i.e., layered slicing, to obtain the contour of each layer’s cross-section. According to these contours, a laser beam selectively cuts layer by layer of paper (or cures layer by layer of liquid resin, sinters layer by layer of powdered material), or a spraying source selectively sprays layer by layer of adhesive or thermoplastic material, forming the cross-sectional contours and gradually stacking them into a three-dimensional product. Rapid prototyping technology completely breaks away from the traditional ‘subtractive’ manufacturing method (i.e., partially removing material from a workpiece to obtain the final part) and adopts a new ‘additive’ manufacturing method (i.e., gradually stacking layers of small stock to build a large workpiece), decomposing complex 3D processing into combinations of simple 2D processing. Therefore, it does not require traditional machining equipment and molds, and only needs 30% to 50% of the labor time and 20% to 35% of the cost of traditional manufacturing methods to directly produce product prototypes or molds. Through rapid prototyping technology, design concepts can be automatically, directly, quickly, and accurately transformed into functional models or directly manufactured products, thereby allowing rapid evaluation, modification, and functional testing of product designs, greatly shortening the product development cycle. Applying rapid prototyping technology in a company’s new product development process can significantly shorten the development cycle of new products, ensure timely market launch, and improve the company’s rapid response to market changes. At the same time, it can reduce mold risks and new product development costs, promptly identify design errors for early correction, avoid substantial losses caused by changes in subsequent processes, and improve the first-time success rate of new product production. Therefore, the application of rapid prototyping technology has become an important strategy in new product development in the manufacturing industry. Rapid prototyping technology is a new technology that integrates advanced technologies such as computer-aided design (CAD), computer-aided manufacturing (CAM), computer numerical control (CNC), precision servo drives, lasers, and materials science. Its basic concept is that any three-dimensional part can be regarded as many two-dimensional plane contours of equal thickness stacked along a coordinate direction. Therefore, based on the three-dimensional design model created on a computer, the 3D model in the CAD system can first be divided into a series of planar geometric information, i.e., layered slicing, to obtain the contour of each layer’s cross-section. According to these contours, a laser beam selectively cuts layer by layer of paper (or cures layer by layer of liquid resin, sinters layer by layer of powdered material), or a spraying source selectively sprays layer by layer of adhesive or thermoplastic material, forming the cross-sectional contours and gradually stacking them into a three-dimensional product. Rapid prototyping technology completely breaks away from the traditional ‘subtractive’ manufacturing method (i.e., partially removing material from a workpiece to obtain the final part) and adopts a new ‘additive’ manufacturing method (i.e., gradually stacking layers of small stock to build a large workpiece), decomposing complex 3D processing into combinations of simple 2D processing. Therefore, it does not require traditional machining equipment and molds, and only needs 30% to 50% of the labor time and 20% to 35% of the cost of traditional manufacturing methods to directly produce product prototypes or molds. Through rapid prototyping technology, design concepts can be automatically, directly, quickly, and accurately transformed into functional models or directly manufactured products, thereby allowing rapid evaluation, modification, and functional testing of product designs, greatly shortening the product development cycle. Applying rapid prototyping technology in a company’s new product development process can significantly shorten the development cycle of new products, ensure timely market launch, and improve the company’s rapid response to market changes. At the same time, it can reduce mold risks and new product development costs, promptly identify design errors for early correction, avoid substantial losses caused by changes in subsequent processes, and improve the first-time success rate of new product production. Therefore, the application of rapid prototyping technology has become an important strategy in new product development in the manufacturing industry.

Rapid prototyping technology completely breaks away from the traditional ‘subtractive’ manufacturing method (i.e., partially removing material from a workpiece to obtain the final part) and adopts a new ‘additive’ manufacturing method (i.e., gradually stacking layers of small stock to build a large workpiece), decomposing complex 3D processing into combinations of simple 2D processing. Therefore, it does not require traditional machining equipment and molds, and only needs 30% to 50% of the labor time and 20% to 35% of the cost of traditional manufacturing methods to directly produce product prototypes or molds. Through rapid prototyping technology, design concepts can be automatically, directly, quickly, and accurately transformed into functional models or directly manufactured products, thereby allowing rapid evaluation, modification, and functional testing of product designs, greatly shortening the product development cycle. Applying rapid prototyping technology in a company’s new product development process can significantly shorten the development cycle of new products, ensure timely market launch, and improve the company’s rapid response to market changes. At the same time, it can reduce mold risks and new product development costs, promptly identify design errors for early correction, avoid substantial losses caused by changes in subsequent processes, and improve the first-time success rate of new product production. Therefore, the application of rapid prototyping technology has become an important strategy in new product development in the manufacturing industry. Rapid prototyping technology is a new technology that integrates advanced technologies such as computer-aided design (CAD), computer-aided manufacturing (CAM), computer numerical control (CNC), precision servo drives, lasers, and materials science. Its basic concept is that any three-dimensional part can be regarded as many two-dimensional plane contours of equal thickness stacked along a coordinate direction. Therefore, based on the three-dimensional design model created on a computer, the 3D model in the CAD system can first be divided into a series of planar geometric information, i.e., layered slicing, to obtain the contour of each layer’s cross-section. According to these contours, a laser beam selectively cuts layer by layer of paper (or cures layer by layer of liquid resin, sinters layer by layer of powdered material), or a spraying source selectively sprays layer by layer of adhesive or thermoplastic material, forming the cross-sectional contours and gradually stacking them into a three-dimensional product. Rapid prototyping technology completely breaks away from the traditional ‘subtractive’ manufacturing method (i.e., partially removing material from a workpiece to obtain the final part) and adopts a new ‘additive’ manufacturing method (i.e., gradually stacking layers of small stock to build a large workpiece), decomposing complex 3D processing into combinations of simple 2D processing. Therefore, it does not require traditional machining equipment and molds, and only needs 30% to 50% of the labor time and 20% to 35% of the cost of traditional manufacturing methods to directly produce product prototypes or molds. Through rapid prototyping technology, design concepts can be automatically, directly, quickly, and accurately transformed into functional models or directly manufactured products, thereby allowing rapid evaluation, modification, and functional testing of product designs, greatly shortening the product development cycle. Applying rapid prototyping technology in a company’s new product development process can significantly shorten the development cycle of new products, ensure timely market launch, and improve the company’s rapid response to market changes. At the same time, it can reduce mold risks and new product development costs, promptly identify design errors for early correction, avoid substantial losses caused by changes in subsequent processes, and improve the first-time success rate of new product production. Therefore, the application of rapid prototyping technology has become an important strategy in new product development in the manufacturing industry.

Principle of SLA

Abbreviation of “Stereo Lithography Apparatus,” which refers to the stereolithography (SLA) method.

Rapid prototyping technology is a new technology that integrates advanced technologies such as computer-aided design (CAD), computer-aided manufacturing (CAM), computer numerical control (CNC), precision servo drives, lasers, and materials science. Its basic concept is that any three-dimensional part can be regarded as many two-dimensional plane contours of equal thickness stacked along a coordinate direction. Therefore, based on the three-dimensional design model created on a computer, the 3D model in the CAD system can first be divided into a series of planar geometric information, i.e., layered slicing, to obtain the contour of each layer’s cross-section. According to these contours, a laser beam selectively cuts layer by layer of paper (or cures layer by layer of liquid resin, sinters layer by layer of powdered material), or a spraying source selectively sprays layer by layer of adhesive or thermoplastic material, forming the cross-sectional contours and gradually stacking them into a three-dimensional product. Rapid prototyping technology completely breaks away from the traditional ‘subtractive’ manufacturing method (i.e., partially removing material from a workpiece to obtain the final part) and adopts a new ‘additive’ manufacturing method (i.e., gradually stacking layers of small stock to build a large workpiece), decomposing complex 3D processing into combinations of simple 2D processing. Therefore, it does not require traditional machining equipment and molds, and only needs 30% to 50% of the labor time and 20% to 35% of the cost of traditional manufacturing methods to directly produce product prototypes or molds. Through rapid prototyping technology, design concepts can be automatically, directly, quickly, and accurately transformed into functional models or directly manufactured products, thereby allowing rapid evaluation, modification, and functional testing of product designs, greatly shortening the product development cycle. Applying rapid prototyping technology in a company’s new product development process can significantly shorten the development cycle of new products, ensure timely market launch, and improve the company’s rapid response to market changes. At the same time, it can reduce mold risks and new product development costs, promptly identify design errors for early correction, avoid substantial losses caused by changes in subsequent processes, and improve the first-time success rate of new product production. Therefore, the application of rapid prototyping technology has become an important strategy in new product development in the manufacturing industry.

Principle of SLA

Abbreviation of “Stereo Lithography Apparatus,” which refers to the stereolithography (SLA) method.

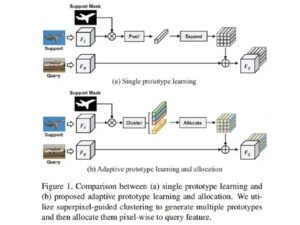

A laser with a specific wavelength and intensity is focused on the surface of a photosensitive material, causing it to solidify sequentially from points to lines, and from lines to surfaces, completing the drawing of one layer. Then, the platform moves vertically by the height of one layer, and another layer is solidified. In this way, layers are stacked to form a three-dimensional object. SLA is the earliest practical rapid prototyping technology, using liquid photosensitive resin as the raw material. The process principle is shown in Figure 1. The process is as follows: first, a 3D model is designed using CAD, then the model is sliced using discrete programming, and the scanning path is designed. The generated data precisely controls the movement of the laser scanner and the platform. The laser beam, guided by a CNC-controlled scanner, irradiates the surface of the liquid photosensitive resin according to the designed scanning path. After a layer of resin in a specific area solidifies, a cross-section of the part is formed. Then, the platform lowers by a certain distance, covering the solidified layer with another layer of liquid resin, and a second layer scanning is performed. The second cured layer firmly bonds to the previous layer, and in this way, the 3D prototype is built up layer by layer. After the prototype is removed from the resin, it undergoes final curing and can then be polished, plated, painted, or colored to obtain the desired product. SLA technology is mainly used to manufacture various molds and models. By adding other components to the raw material, SLA prototypes can also replace wax models in investment casting. SLA technology has a relatively fast forming speed and high accuracy, but since resin shrinkage occurs during curing, stress or deformation is inevitably generated. Therefore, developing photosensitive materials with low shrinkage, fast curing, and high strength is a trend in its development. The Viper Pro SLA system was introduced by 3D Systems.

Advantages of SLA

1. Stereolithography (SLA) is the earliest rapid prototyping manufacturing process, highly mature and proven over time.

2. Prototypes are made directly from CAD digital models, offering fast processing speed, short production cycles, and no need for cutting tools or molds.

3. Capable of producing prototypes and molds with complex structures or those difficult to form using traditional methods.

4. Visualizes CAD digital models, reducing the cost of correcting errors.

5. Provides samples for experiments, allowing verification and calibration of computer simulation results.

6. Can be operated online and remotely, facilitating automated production.

Drawbacks of SLA

1. SLA systems are expensive, with high operational and maintenance costs.

2. SLA systems are precision equipment that handle liquids, requiring strict working environments.

3. Most formed parts are made of resin, with limited strength, rigidity, and heat resistance, making long-term preservation difficult.

4. Pre-processing and driver software require heavy computation and are highly correlated with processing results.

5. The software system is complex and difficult to learn; the file formats used are not familiar to most designers.

6. Stereolithography technology is monopolized by a single company.

Trends and Prospects of SLA

The development trend of stereolithography is towards high speed, energy saving, environmental protection, and miniaturization.

Continuously improving processing accuracy makes it likely to play a major role in fields such as biology, medicine, and microelectronics.

The Best Brands Put Their Trust in Formex