Cost Calculator

Automotive Injection Molding Service: Custom Solutions for Car Parts Manufacturing

- A leader in plastic injection molding

- Injection Molding Cost Calculator, Get Online Quotes in 24Hours

- Parts shipped in as little as 15 days

- The world’s only 24-Hours injection molding quote

- Low-Cost Injection Molding Leader

- All uploads are secure and confidential

Trusted by over 2,000 engineers & purchasing leaders worldwide![]()

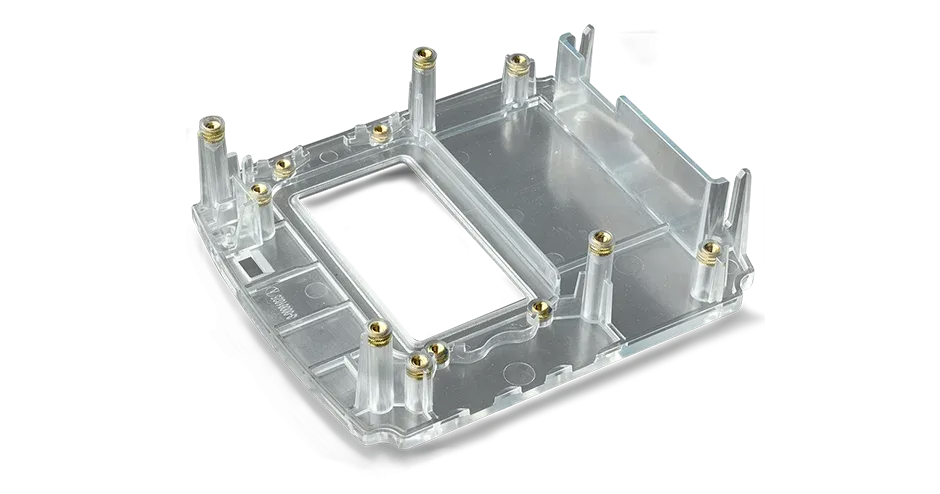

We are a contract manufacturer for custom plastic injection molding. Our customers come to us with their product designs, and we manufacture the injection mold tooling to make their plastic parts. We work with a wide range of customers, with varying levels of knowledge about plastic injection molding. Our customers range from large, multinational appliance manufacturers, all the way down to inventors with an idea for a new product. In fact, a number of our customers are entrepreneurs with an idea for a new product that’s never been invented before, or for improving an existing product – making a “better mouse trap.” Many have never worked with a plastic injection molder before and this is all new to them.

entrepreneurs with an idea for a new product that’s never been invented before, or for improving an existing product – making a “better mouse trap.” Many have never worked with a plastic injection molder before and this is all new to them.

Since there is such a wide range of prior injection molding knowledge and experience, it is helpful to have a basic understanding of the main terms used in plastic injection molding so we can communicate with our customers about their projects.

The injection molding glossary below is provided to help define the most common terms used in the industry. You can also use the search box at the top of the table to search for a term.

Terms Definition

Aging

The change of a material with time under defined environmental conditions, leading to improvement or deterioration of properties

Barrel

The part of the molding press where resin is melted.

Boss

The round protrusions on plastic parts, often designed for fasteners.

Bridge Tool

This review evaluates all design changes that need to be made and reviews the proposed molding strategy on all parts. 2D drawings are reviewed for characteristics to be controlled in production. CMF (color, material, finish) is finalized along with the production schedule.

Over-packing or under-packing results in less than optimum fill.