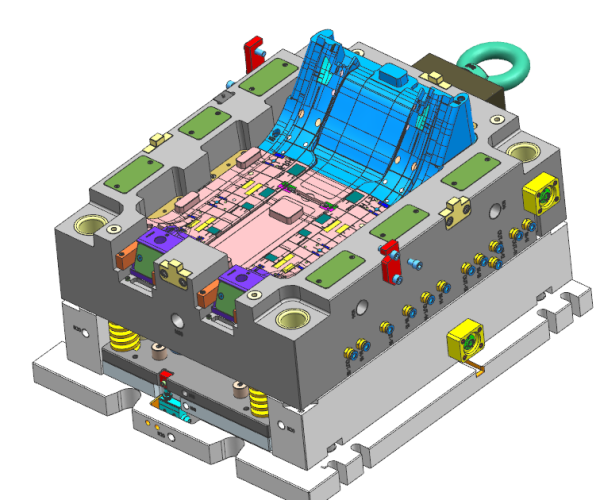

Mold manufacturing

Automotive Injection Molding Service:

- A leader in plastic injection molding

- Injection Molding Cost Calculator, Get Online Quotes in 24Hours

- Parts shipped in as little as 15 days

- The world’s only 24-Hours injection molding quote

- Low-Cost Injection Molding Leader

- All uploads are secure and confidential

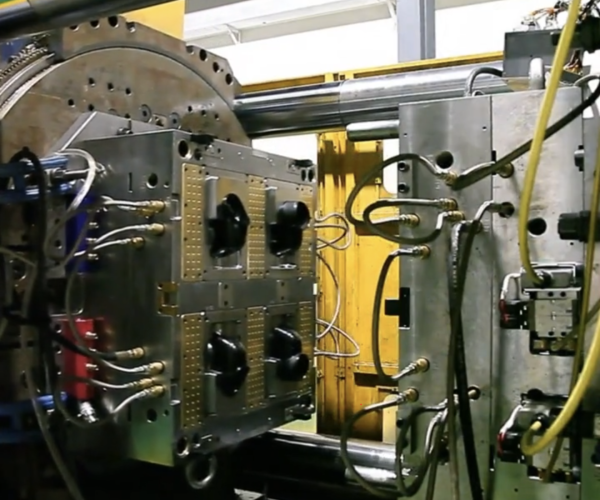

Domestically produced injection moulding moulds

The design of domestically produced injection moulds focuses on helping customers reduce development costs, generally using P20 steel or NK80, and typically withstanding over 100,000 cycles.As long as we continue to make your parts in our facility, we will maintain and repair the tool as needed at our cost.

Can I make design changes on production molds?

Yes, making design changes on production molds is possible with FormexMold. An FormexMold engineer will coordinate with you on CAD file changes and rework the mold accordingly. You will receive revised samples for your approval prior to production.

FormexMold provides a dedicated project manager and engineer for your injection molding production. Please check out FormexMold’s Online Project Management System.

Export mould standards

I.International Standards

1. ISO System

Dimensional tolerances follow ISO 2768 (medium precision) or ISO 20457 (tolerances for plastic parts), and critical dimensions must be verified using a coordinate measuring machine (CMM). Material properties must comply with ISO 11469 (plastic classification) and ISO 10993 (biocompatibility, applicable to medical moulds).

2. Regional Standards

Europe adopts the HASCO standard, with components such as guide pillars and ejector pins required to comply with DIN EN ISO 286 (dimensional tolerances). The Americas use inch-based mould bases (such as DME standards), with designs required to meet ASTM D1693 (environmental stress cracking test). Asia refers to JIS B 5705 (Japanese mould standard) or KS B 6921 (Korea), focusing on the layout of cooling channels and insert design.

2. Material and Environmental Requirements

1. Compliance of Raw Materials

Steel must be imported from the original manufacturer with material certification provided (e.g., P20, 718H, NAK80, S136, etc.), and hardness after heat treatment should reach HRC48-52 to ensure a mould life of millions of cycles. Moulds in contact with food must comply with FDA 21 CFR 177.1520 (USA) or EU 10/2011 (EU) certification, with strict control over heavy metal migration (e.g., lead ≤ 0.01mg/kg).

2. Environmental Directives

Comply with RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals), prohibiting the use of harmful substances such as lead and mercury. Cutting fluids must meet ISO 15380 (biodegradability requirements).

3. Design and Manufacturing Specifications

1. Structural Design

Adopt a modular insert design, using hardened wear-resistant blocks (HRC58-62) for vulnerable parts (such as clips and deep cavities) to facilitate replacement.

Cooling channels should be analysed using Moldflow, ensuring a mould cavity temperature difference ≤3℃ to prevent product shrinkage and deformation.

2. Precision Control

Parting surface gap ≤0.03mm, ejection system stroke deviation ≤0.5mm, key dimensional tolerances controlled at ±0.01mm (IT5 grade).

Surface treatments may include nitriding (case depth 0.1-0.3mm) or hard chrome plating (thickness 0.02-0.05mm), Ra ≤0.1μm (mirror finish required).

4. Certification and Safety Standards

1. Market Access Certification

EU CE: Must comply with the Machinery Directive (MD) 2006/42/EC, meeting EN ISO 20430:2020 (injection moulding machine safety) and EN 60204-1 (electrical safety).

North America UL: Electrical components must be certified under UL 508 (industrial control equipment), and packaging must comply with ISTA 3A (transport shock resistance).

2. Safety Design

Equipped with low-pressure mould closing protection (pressure ≤ 15% of the maximum mould closing force), photoelectric safety light curtains, and emergency stop devices (EN ISO 13850).

High-temperature components (such as the glue barrel) must have thermal insulation protection, and warning signs must be placed if the surface temperature exceeds 60°C.

5. Packaging and Transportation Standards.

1. Protection Requirements

Use Grade A fumigation wooden crates (compliant with IPPC international plant quarantine), with internal dimensions >100mm larger than the mould outline, reinforced with steel straps (≥2 per side). After applying anti-rust paint on the mould, seal it in a waterproof plastic bag, package accessories separately with anti-rust protection, and include a packing list, assembly diagram and trial mould sample in the crate.

2. Labelling and Documentation

Mark the wooden crate with the product name, weight, lifting points, and "Fragile" and "Moisture Proof" labels, in accordance with GB/T 191 (packaging storage and transportation illustrations). Provide English technical documents including material reports, inspection certificates, maintenance manuals and EU Declaration of Conformity (DoC).

6. Industry-specific requirements

Medical moulds: Must comply with ISO 13485 (medical device quality management system), cavity surface roughness Ra ≤ 0.05 μm, using 316L stainless steel to prevent corrosion.

Automotive moulds: Must comply with IATF 16949 (automotive industry quality system), part dimension CPK ≥ 1.33, with service life verification exceeding 500,000 cycles.

Our Custom Mold Making Capabilities

We specialize in creating high-performance injection molds for plastic components, from single-cavity to multi-cavity designs.

In-house mold design and engineering support

One-stop mold making & injection molding services

Cost-effective production in China

Mold Design

“We’ve partnered with Formex for 20 Years on medical molds. Their ISO13485 compliance and fast tweak responses always meet our strict standards, saving us time.”

Mold Making

“We’ve partnered with Formex for 3 years on auto parts. Their IATF16949 compliance and on-time delivery keep production smooth, super reliable.”

Mold Trial & Injection Molding

“15+ years of experience shows. Formex delivers custom precision parts on time, and their support team solves issues fast. A true partner for our projects.”

Quality Control

“15+ years of experience shows. Formex delivers custom precision parts on time, and their support team solves issues fast. A true partner for our projects.”

How to Work With Us

![]()

Mould making process

At Formexmold, every injection mold is built under ISO 9001 standards with CNC tolerances as tight as ±0.01 mm and strict trial-run verification, ensuring durability and production stability for mass manufacturing.

Material Preparation

Select high-strength steel or other materials based on design requirements, and perform necessary pre-treatments (e.g., quenching, annealing, or tempering) to enhance durability and machinability.

Mold Part Machining

We utilize advanced equipment for machining mold components, including CNC machining to ensure precision for complex parts, electrical discharge machining (EDM) for creating intricate cavities and high-precision mold components, and wire cutting to achieve precise cuts and detailed finishes.

Heat Treatment

Perform heat treatment to improve the hardness, strength, and wear resistance of mold parts, ensuring robustness for high-strength production.

Surface Treatment

Apply surface treatments such as polishing, plating, or nitriding to enhance surface smoothness and durability, ensuring stable performance during production.

Mold Assembly

Assemble machined components into a complete mold, ensuring all parts fit seamlessly and comply with design specifications.

Testing and Trial Runs

After initial assembly, conduct multiple rounds of testing and trial production to evaluate the mold's performance. Make necessary optimizations to ensure it meets actual production needs.

Mold Manufacturing Materials

We have access to over 50+ metals and plastics to use for any manufacturing process.

Aluminum

One of the most common metals used in machining. It is highly malleable, which makes it a great machining choice. It has a high thermal conductivity, making it suitable for manufacturing parts to be used in high-heat applications. It also has various types used in multiple applications. It is for prototype mold.

P20 (P20H)

Also known as low-carbon steel. Has good malleability and high tensile strength—also a very cost-effective choice for suitable applications. Hot work mold steel material.

718 (718H)

718H is a pre-hardened mirror-finish acid-resistant plastic mould steel, corresponding to China's GB standard 3Cr2NiMo, Germany's DIN standard 1.2311, Sweden's ASSAB standard 718, USA's AISI/SAE P20 improved type, Japan's JS standard SNCM improved type, and the international standard ISO 35CrMo2. This chrome-nickel-molybdenum alloy steel is vacuum melted and pre-hardened (33~38HRC), featuring no risk of distortion during heat treatment, excellent polishing performance, and high hardenability, and it supports nitriding and flame hardening (up to 52HRC). It is for prototype mold.

2344 (H13)

Renowned for its lightness and strength. It also has high corrosion resistance, so longevity is assured. Its excellent strength-to-weight ratio makes it a great choice for high-strength applications. It also has a low thermal expansion coefficient, making it less susceptible to expansion due to heat. It is for prototype mold.

2083 (420SS)

Quite visually appealing due to its beautiful aesthetics. It is also very durable and corrosion resistant, making it an excellent choice for many plastic molding manufacturing applications.It is stainless steel.

Types of Injection Molds We Manufacture

Choosing the right injection mold for your project is crucial, as different mold types will directly impact production efficiency, product quality, and cost. Based on your needs and production scale, there are various types of injection molds available.

Low-Cost Injection Molding Leader

The Best Brands Put Their Trust in Formex